About Me

At Work

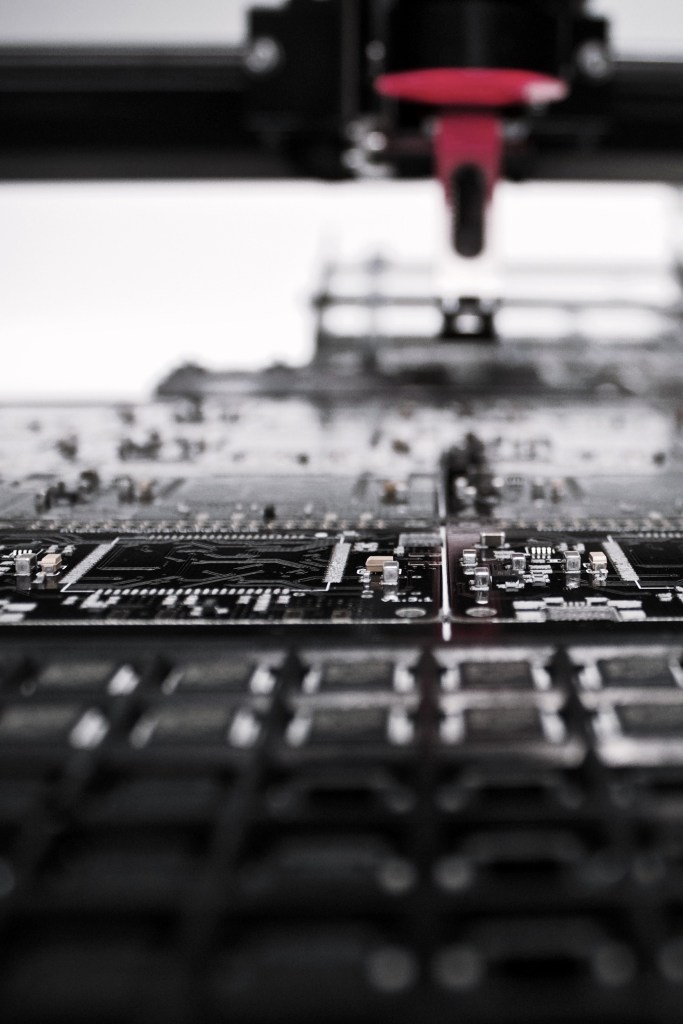

I enjoy working on complex problems with a talented team. I gravitate towards anything high-tech, still get a thrill from seeing a robot do what I programmed it to do, and get excited about turning data into insight, and insight into solutions.

At Home

I love cooking, reading, and being outdoors. My most recent hiking adventures were the Rocky Mountains, the Grand Canyon, and Redwood National Park.